Richter engineer solutions to enable replacement footbridge works.

Published: 22/03/2022 10:02

Richter supported Story Contracting with temporary works designs during the bridge replacement scheme at Townthorn, a footbridge spanning across four rail lines linking Nuneaton to Rugby.

The liftout was to take place during an overnight possession, using a 350 tonne mobile crane alongside the line. Richter's engineers provided a design for the crane platform, utilising their expertise in the Tensar T-value method to offer a solution which utilised Triax geogrid to deliver cost and time savings, also reducing the amount of materials that needed to be delivered to site, whilst maintaining a stable and working platform.

The bridge consisted of a pair of girders, which had been raised up on haunches to clear the OLE, with a timber deck spanning between. Due to its unusual layout, the central span with its haunches was to be cut and lifted clear of the structure, removing all of the elements overhanging the line and leaving the staircases with their landings to be dismantled separately.

|  | |

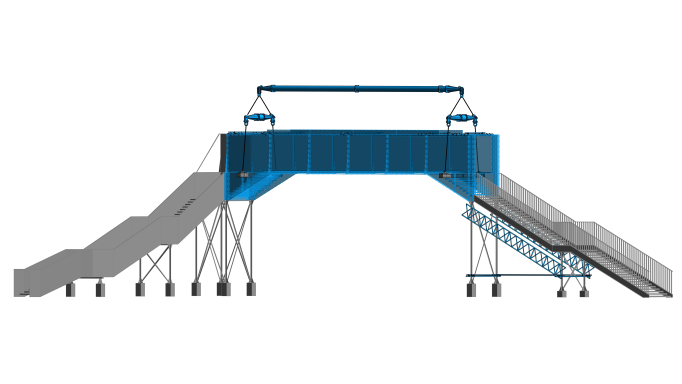

| Townthorn footbridge prior to it being replaced. | Example of a 3D project model produced by Richter's engineers forming part of the sequence of works. |

Richter assessed the bridge girders to ensure that they had sufficient capacity to be lifted out using chains passed through holes cut in the webs. This avoided the difficulty of raising support beams to the underside of the deck as the OLE was to remain in place throughout. Support trestles were designed, allowing the sections of the new deck to be welded together on site and also providing a stable support for safe dismantling of the old deck.

To assist in the installation of the new bridge, formwork designs were provided for casting the concrete footings of its staircases. Finally, assessments were carried out to ensure that the feed from a concrete pump, protected using a plastic pipe, could be passed beneath the rails without the risk of undermining their support zone. This was vital for safely running trains through the work site during the period that the works were to take place.